Ishan Vats

Introduction

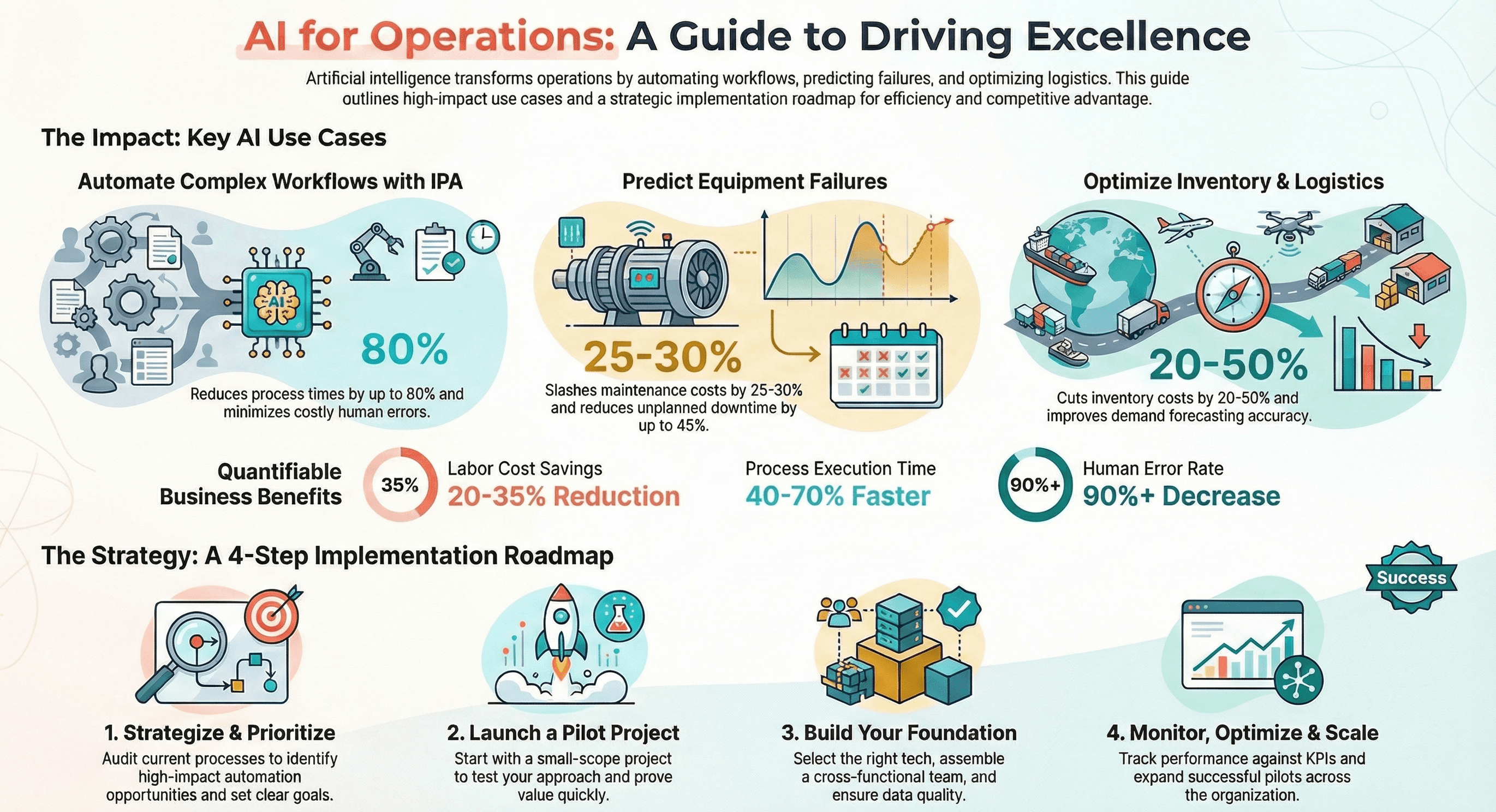

In today's rapidly evolving business landscape, operations teams are under constant pressure to deliver more with less—higher efficiency, lower costs, and faster turnaround times. Artificial Intelligence (AI) and automation have emerged as game-changing technologies that can help operations teams meet these demands while freeing up valuable time for strategic initiatives.

This comprehensive guide explores the most impactful use cases of AI and automation for operations teams, along with practical implementation strategies, measurable benefits, and future trends that will shape the industry.

Why AI & Automation Matter for Operations Teams

Operations teams are the backbone of any organization, responsible for ensuring smooth workflows, resource optimization, and timely delivery of products or services. However, traditional operational processes often involve:

Repetitive manual tasks that consume valuable time

Data silos that prevent holistic decision-making

Reactive problem-solving rather than proactive prevention

Limited visibility into real-time performance metrics

AI and automation technologies address these challenges by enabling operations teams to work smarter, make data-driven decisions, and focus on high-value activities that drive business growth.

Top AI & Automation Use Cases for Operations Teams

1. Intelligent Process Automation (IPA)

What it is: Intelligent Process Automation combines Robotic Process Automation (RPA) with AI capabilities like machine learning, natural language processing, and computer vision to automate complex business processes.

How operations teams use it:

Automating invoice processing and accounts payable workflows

Streamlining employee onboarding and offboarding processes

Automating data entry and validation across multiple systems

Processing and categorizing customer requests automatically

Benefits: IPA can reduce processing times by up to 80%, minimize human errors, and allow team members to focus on exception handling and strategic work.

2. Predictive Maintenance

What it is: AI-powered predictive maintenance uses machine learning algorithms to analyze equipment data and predict potential failures before they occur.

How operations teams use it:

Monitoring equipment health through IoT sensors and real-time data analysis

Predicting maintenance needs based on usage patterns and historical data

Scheduling proactive maintenance during optimal downtime windows

Reducing unplanned equipment failures and production disruptions

Benefits: Companies implementing predictive maintenance have reported 25-30% reduction in maintenance costs, 70-75% fewer breakdowns, and 35-45% reduction in downtime.

3. Supply Chain Optimization

What it is: AI algorithms analyze vast amounts of supply chain data to optimize inventory levels, predict demand, and improve logistics efficiency.

How operations teams use it:

Demand forecasting using historical sales data and market trends

Dynamic inventory management to reduce stockouts and excess inventory

Route optimization for delivery and logistics operations

Supplier risk assessment and performance monitoring

Benefits: AI-driven supply chain optimization can reduce inventory costs by 20-50%, improve forecast accuracy by 10-20%, and enhance on-time delivery rates.

4. Quality Control & Inspection

What it is: Computer vision and machine learning enable automated quality inspection with higher accuracy and consistency than manual processes.

How operations teams use it:

Automated visual inspection of products on production lines

Defect detection and classification in real-time

Quality trend analysis and root cause identification

Compliance monitoring and documentation

Benefits: Automated quality control can inspect 100% of products (versus sample-based manual inspection), detect defects with 99%+ accuracy, and reduce quality-related costs.

5. Workforce Management & Scheduling

What it is: AI-powered workforce management systems optimize employee scheduling, task allocation, and resource planning based on demand forecasts and employee preferences.

How operations teams use it:

Automated shift scheduling based on demand patterns and employee availability

Skills-based task assignment to match work with qualified personnel

Labor cost optimization while maintaining service levels

Predictive workforce planning for seasonal variations

Benefits: Intelligent workforce management can reduce labor costs by 10-15%, improve employee satisfaction, and ensure optimal staffing levels.

6. Customer Service Automation

What it is: AI-powered chatbots and virtual assistants handle customer inquiries, provide instant support, and route complex issues to human agents.

How operations teams use it:

24/7 automated customer support for common inquiries

Intelligent ticket routing and prioritization

Sentiment analysis to identify urgent customer issues

Self-service knowledge base with AI-powered search

Benefits: Customer service automation can handle 60-80% of routine inquiries, reduce response times by 90%, and significantly lower support costs.

7. Document Processing & Management

What it is: AI-powered document processing uses natural language processing and optical character recognition to extract, classify, and process information from unstructured documents.

How operations teams use it:

Automated extraction of data from invoices, receipts, and forms

Intelligent document classification and routing

Contract analysis and compliance checking

Automated data validation and verification

Benefits: Document automation can reduce processing time by 70-90%, improve accuracy, and eliminate manual data entry bottlenecks.

8. Operations Analytics & Reporting

What it is: AI-powered analytics platforms provide real-time insights, predictive analytics, and automated reporting to support data-driven decision-making.

How operations teams use it:

Real-time operational dashboards with KPI tracking

Predictive analytics for resource planning and capacity management

Anomaly detection to identify operational issues early

Automated report generation and distribution

Benefits: Advanced analytics enable faster decision-making, proactive problem resolution, and continuous operational improvement.

Implementation Strategies for AI & Automation

Successfully implementing AI and automation in operations requires a strategic approach. Here's a proven framework:

Step 1: Assess Your Current Operations

Conduct a comprehensive process audit to identify automation opportunities

Map current workflows and document pain points

Identify processes with high volume, repetitive tasks, and clear rules

Evaluate data availability and quality for AI applications

Step 2: Define Clear Objectives

Set specific, measurable goals for your automation initiatives

Align automation projects with broader business objectives

Establish success metrics and KPIs to track progress

Prioritize use cases based on potential impact and feasibility

Step 3: Start Small with Pilot Projects

Begin with a limited-scope pilot to validate the approach

Choose a process that offers quick wins and measurable results

Test and refine before scaling across the organization

Gather feedback from end-users and stakeholders

Step 4: Choose the Right Technology Stack

Evaluate automation platforms based on your specific needs

Consider integration capabilities with existing systems

Assess scalability, security, and vendor support

Balance between build vs. buy decisions

Step 5: Build a Cross-Functional Team

Include operations staff, IT professionals, and business analysts

Appoint automation champions within the operations team

Provide training and upskilling opportunities

Foster a culture of innovation and continuous improvement

Step 6: Ensure Data Quality & Governance

Establish data quality standards and validation processes

Implement data governance policies and security measures

Ensure compliance with relevant regulations (GDPR, HIPAA, etc.)

Create data access controls and audit trails

Step 7: Monitor, Measure, and Optimize

Track performance metrics against baseline and targets

Conduct regular reviews and optimization sessions

Gather user feedback and address issues promptly

Scale successful pilots across the organization

Benefits and ROI of AI & Automation

Organizations that successfully implement AI and automation in their operations typically experience significant benefits across multiple dimensions:

Operational Efficiency

Time savings: 40-70% reduction in process execution time

Throughput improvement: 2-3x increase in processing capacity

Resource optimization: 25-40% improvement in resource utilization

Cycle time reduction: Faster turnaround on critical operations

Cost Reduction

Labor cost savings: 20-35% reduction through automation of routine tasks

Error reduction: 90%+ decrease in human errors and rework costs

Operational costs: 15-30% reduction in overall operational expenses

Maintenance costs: 25-30% savings through predictive maintenance

Quality Improvement

Accuracy: 99%+ accuracy in automated processes

Consistency: Standardized execution across all transactions

Compliance: Improved adherence to regulatory requirements

Customer satisfaction: Enhanced service quality and responsiveness

Strategic Benefits

Scalability: Ability to handle growth without proportional cost increases

Agility: Faster response to market changes and opportunities

Innovation: Free up teams to focus on strategic initiatives

Competitive advantage: Differentiation through operational excellence

Calculating ROI

A typical ROI calculation for automation projects includes:

Benefits:

Labor cost savings (hours saved × hourly rate)

Error reduction savings (reduced rework and corrections)

Productivity gains (increased throughput value)

Customer satisfaction improvements (retention value)

Costs:

Software licensing and implementation costs

Infrastructure and integration expenses

Training and change management

Ongoing maintenance and support

Most organizations see ROI within 6-18 months, with some quick-win projects delivering positive returns in as little as 3 months.

Common Challenges and Solutions

While AI and automation offer tremendous benefits, implementation can present challenges. Here's how to address the most common ones:

Challenge 1: Resistance to Change

Problem: Employees may fear job loss or resist new ways of working.

Solutions:

Communicate the vision: automation augments human capabilities, not replaces them

Involve employees early in the process and gather their input

Provide comprehensive training and support

Celebrate early wins and share success stories

Redeploy freed-up resources to higher-value activities

Challenge 2: Data Quality Issues

Problem: AI systems require high-quality, consistent data to function effectively.

Solutions:

Conduct data quality assessments before implementation

Implement data cleansing and standardization processes

Establish data governance policies and ownership

Start with processes that have relatively clean data

Plan for ongoing data quality monitoring and improvement

Challenge 3: Integration Complexity

Problem: Connecting automation tools with legacy systems can be technically challenging.

Solutions:

Use API-based integration where possible

Leverage integration platforms and middleware

Consider cloud-based solutions with built-in connectors

Work with experienced integration partners

Plan for a phased integration approach

Challenge 4: Unrealistic Expectations

Problem: Stakeholders may expect immediate, dramatic results from automation.

Solutions:

Set realistic timelines and milestones

Communicate that AI/automation is a journey, not a one-time project

Start with achievable pilot projects to build credibility

Provide regular progress updates and demonstrations

Focus on continuous improvement rather than perfection

Challenge 5: Skills Gap

Problem: Teams may lack the technical skills needed to implement and maintain automation solutions.

Solutions:

Invest in training and upskilling programs

Hire or partner with automation specialists

Choose user-friendly, low-code automation platforms

Build a center of excellence to share knowledge

Create documentation and best practice repositories

Challenge 6: Security and Compliance Concerns

Problem: Automated processes must maintain security standards and regulatory compliance.

Solutions:

Conduct security assessments of automation platforms

Implement role-based access controls

Ensure audit trails and logging capabilities

Work with legal and compliance teams from the start

Choose vendors with strong security credentials

Future Trends in AI & Automation for Operations

The field of AI and automation is rapidly evolving. Here are key trends that will shape the future of operations:

1. Hyperautomation

Hyperautomation combines multiple technologies—RPA, AI, machine learning, process mining, and analytics—to automate as many processes as possible. Organizations are moving beyond automating individual tasks to creating end-to-end automated workflows.

Impact: Operations teams will manage increasingly sophisticated automation ecosystems that handle complex, cross-functional processes with minimal human intervention.

2. Autonomous Operations

Self-learning systems will progressively make decisions and take actions without human oversight, continuously optimizing based on outcomes.

Impact: Operations will shift from manual control to oversight and exception management, with AI handling routine decision-making.

3. Edge AI

AI processing is moving closer to data sources (edge devices) rather than relying solely on centralized cloud computing, enabling real-time decision-making with lower latency.

Impact: Operations teams will benefit from faster response times in manufacturing, logistics, and field operations.

4. Explainable AI (XAI)

As AI becomes more prevalent in operations, there's growing demand for transparency in how AI systems make decisions.

Impact: Operations teams will have better visibility into AI reasoning, improving trust and enabling more effective oversight.

5. AI-Human Collaboration

Rather than replacing humans, AI will increasingly augment human capabilities through collaborative intelligence—AI handling data-intensive tasks while humans focus on creativity, judgment, and relationship-building.

Impact: Operations roles will evolve, with professionals becoming "automation managers" who orchestrate human-AI collaboration.

6. Process Intelligence

Advanced process mining and analytics will provide unprecedented visibility into how work actually gets done, identifying optimization opportunities automatically.

Impact: Operations teams will have data-driven insights to continuously improve processes and prioritize automation investments.

7. Sustainability & Green Operations

AI and automation will play a crucial role in optimizing resource usage, reducing waste, and minimizing environmental impact.

Impact: Operations teams will be able to achieve both efficiency and sustainability goals through intelligent optimization.

8. Industry-Specific AI Solutions

Pre-trained AI models tailored for specific industries will make adoption easier and faster, reducing the need for extensive customization.

Impact: Smaller operations teams will access enterprise-grade AI capabilities through industry-specific solutions.

Conclusion: Embracing the AI-Powered Future of Operations

AI and automation are no longer optional for operations teams seeking to remain competitive in today's fast-paced business environment. From intelligent process automation to predictive maintenance, supply chain optimization to quality control, the use cases are diverse and the benefits are proven.

The key to success lies in approaching AI and automation strategically:

Start with clear objectives aligned to business goals

Begin with pilot projects that deliver quick wins

Invest in your people through training and change management

Focus on data quality as the foundation for AI success

Measure and optimize continuously to maximize ROI

Stay informed about emerging trends and technologies

Organizations that embrace AI and automation today are positioning themselves for long-term success, building capabilities that will compound over time. The question is no longer whether to automate, but how quickly you can do so while maintaining quality and building organizational capabilities.

At IV Consulting, we specialize in helping operations teams navigate their AI and automation journey—from strategy development to implementation and optimization. Our proven frameworks and industry expertise enable organizations to realize measurable value from automation while building sustainable capabilities for the future.

About the Author: This guide was created by the team at IV Consulting, specialists in AI implementation and digital transformation for operations teams. We help organizations across industries leverage technology to drive efficiency, reduce costs, and achieve sustainable competitive advantage.

Your Weekly Newsletter for Smarter Work and Simpler Systems

Get practical insights on AI, automation, and business optimization - without the jargon.

Join 1,000+ business owners, founders, and managers who use our tips to save time, scale faster, and simplify their workflows every week.